Facilitating access to low-carbon energy: using the sun, water, biomass or the wind to produce electricity, store it and make it accessible where and when it is needed.

In 2021, the John Cockerill’s teams have worked, among others, on these emblematic projects:

Reaching the 4 corners of the world

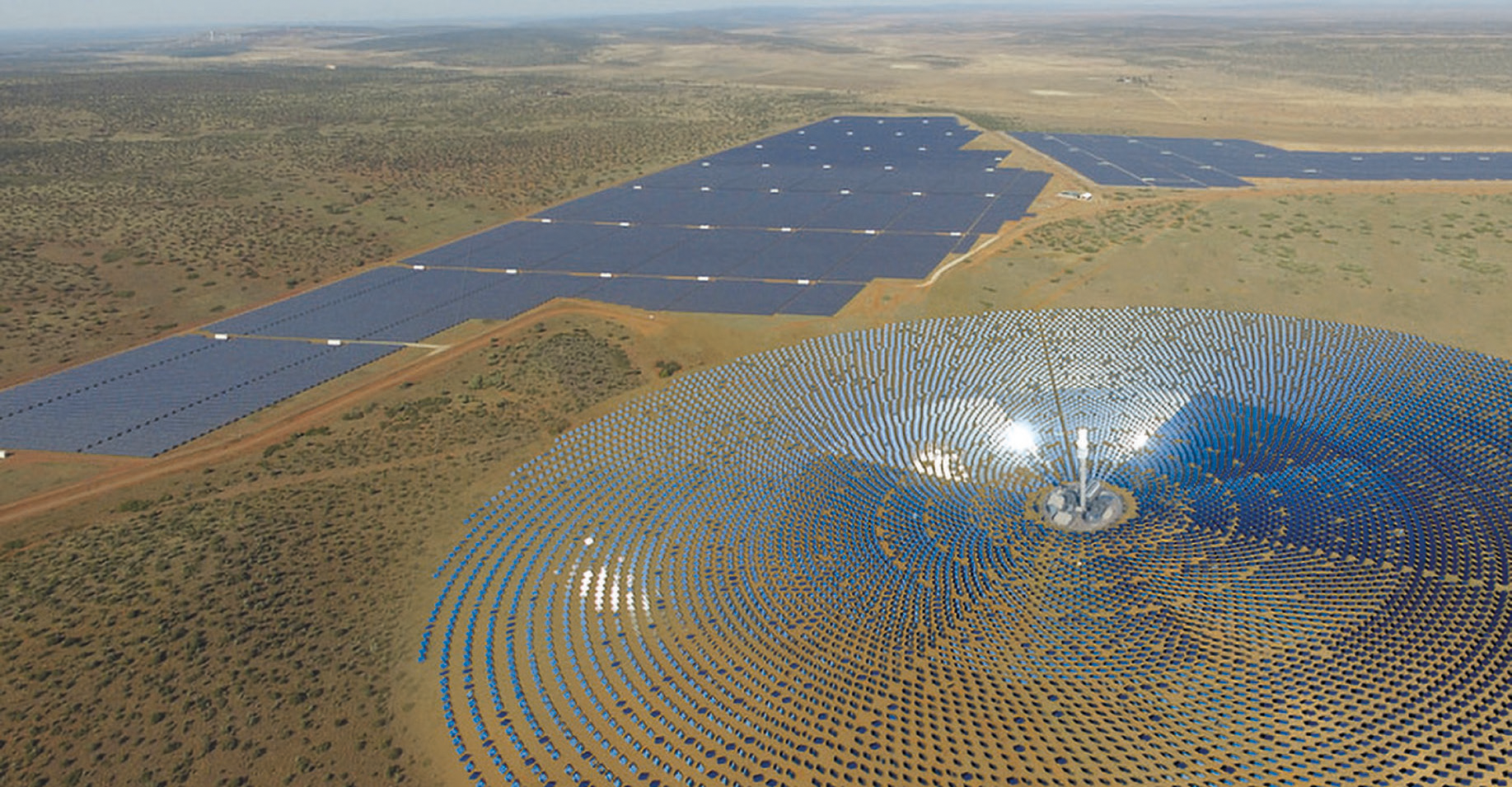

As the world’s leading supplier of molten salt solar receivers, John Cockerill confirmed its position as market leader in 2021 with the signing of a contract to design and supply a thermo-solar receiver for South Africa. With now 5 reference projects for this 100% green electricity production technology around the world, John Cockerill is more than ever positioning itself as a major player in the energy transition.

Five years after the commissioning of Khi Solar One, John Cockerill is returning to South Africa to deliver a new generation thermo-solar receiver. Its second reference project in the country, and the fifth in the world.

Double coup in South Africa

440 000 tonnes of CO2 emissions avoided

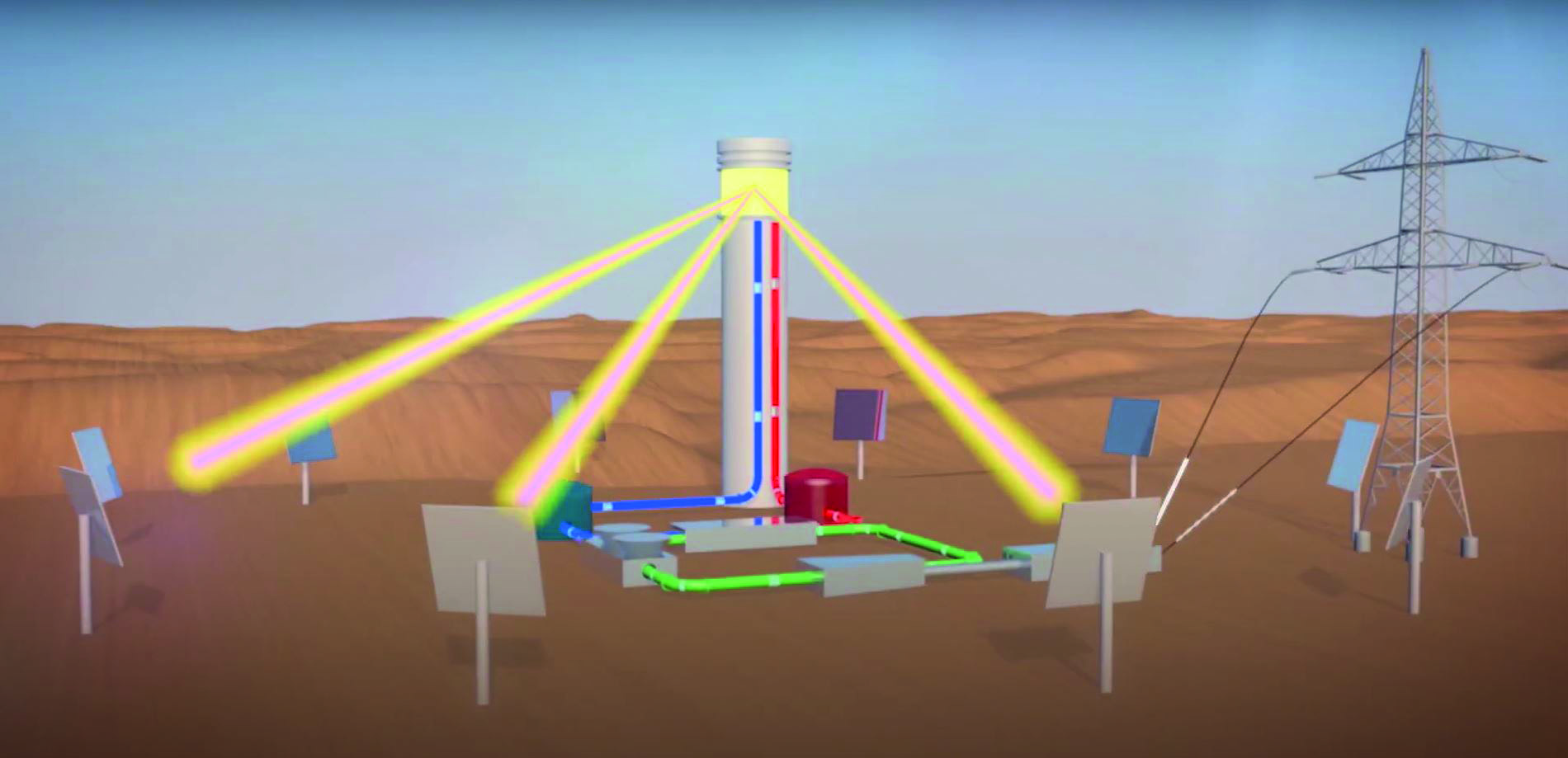

The ABC of solar thermal energy at John Cockerill

Thermo-solar power plants are one of the essential elements of the technological mix that is necessary for the energy transition and the decarbonization of human activities. Here, mirror fields of the MBR Solar Park photographed from the top of the tower.

It shines in Dubai

1.6 million tonnes of CO2 emissions avoided

320 000 households supplied with electricity

CO2 as a heat transfer fluid

The maximum temperature of molten salts, i.e. the heat transfer fluid currently used in’tower‘ thermo-solar power plants, is 565 °C. In order to further increase this temperature and thereby increase the yield and performance of thermo-solar power plants, John Cockerill’s teams are developing solutions that will allow molten salts to be replaced by new heat transfer media that is capable of storing and transferring heat. One of the solutions under study is a suspension of solid particles whose temperature may approach 700 °C. This may be able to supply a density of energy storage 2.5 times greater for an energy storage cost cut in half. Another idea under study, this time within the context of the COMPASsCO2 research project is the use of supercritical CO2 as a working fluid within the thermodynamic cycle for the production of electricity.Here too, research is progressing with the same objective: providing technological responses to the challenge launched by the European Union, the decarbonization of the economy by 2050.

From solar to nuclear

Drawing on its technological expertise in molten salts, and working together with Terrestrial Energy and Engie Laborelec, John Cockerill has been participating in the development of Small Modular Nuclear Reactors (SMRs) since 2021. The contribution of John Cockerill’s teams to this development is focused on studying the corrosion to the various components of these future reactors caused by the molten salts used in SMRs. John Cockerill’s experts have begun the development of a test loop enabling corrosion on these future reactors to be studied over a long period. For John Cockerill, this activity constitutes the perfect bridge between its activities in renewable energies and those in nuclear energy, and confirms John Cockerill’s ambition to facilitate access to low-carbon energies.

- Copied

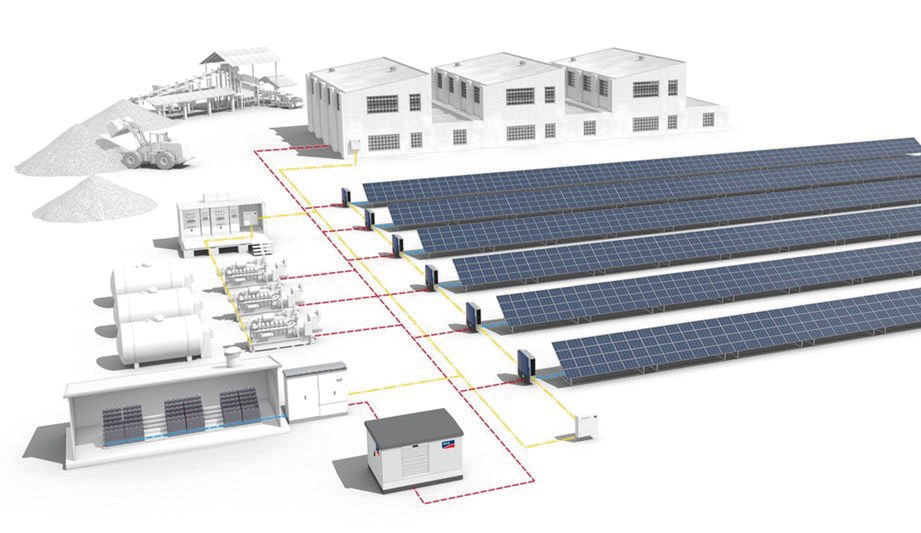

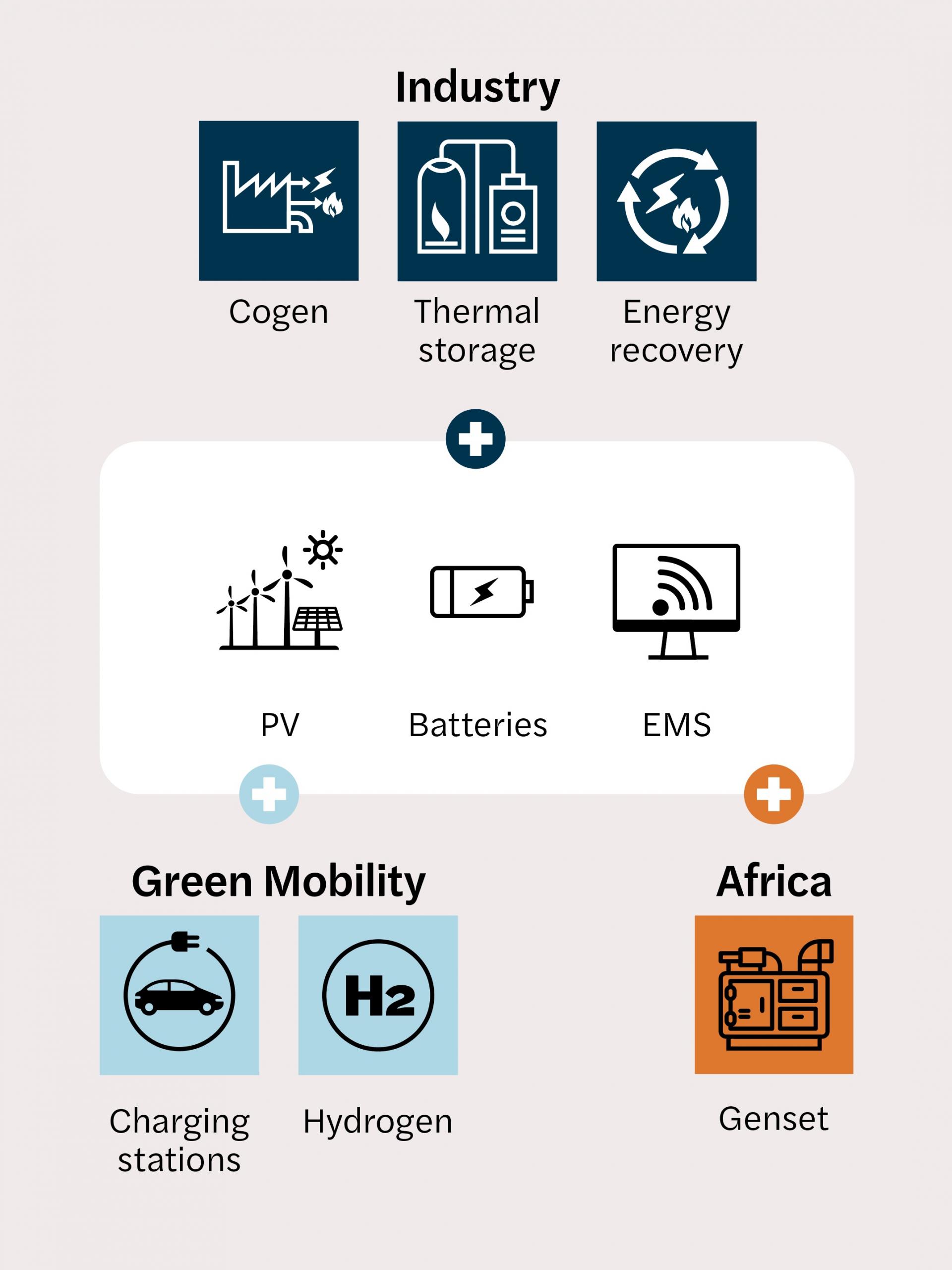

When integrated renewables reduce the carbon footprint and energy bills

Industrialists, transporters and communities: in order to reduce their carbon footprint and their energy bill, John Cockerill offers integrated renewable solutions to three categories of users. At the heart of these solutions: John Cockerill’s Energy Management System, coupled with a skillful combination of solar panels, batteries and specific technologies, depending on the project. The solutions that our teams began in 2021 will avoid more than 10 000 tons of CO2 emissions per year. The energy transition is underway.

John Cockerill is supporting Chad in the gradual deployment of mini-grids, i.e. relatively small, local, green electricity production units (between 10 kW and 10 MW) that are isolated from other power grids.

Electrifying Chad through energy storage

In 2021, John Cockerill won a contract with the Chadian energy company ZIZ to supply and install a lithium-ion battery energy storage system and a transformer. This equipment will make it possible to finalize the hybrid solar electric mini-grid of the city of Mongo, in Chad. Around 3 000 households, artisans, industries and administrative services will thereby be connected to the mini-grid by the end of 2022.

This battery storage system alone will prevent the production of 300 tons of CO2 per year. With these technologies, John Cockerill’s teams are positioning themselves as partners of private energy operators in Chad, on whom the state authorities rely to electrify the country, whose rate of access to electricity is currently only 11%.

9 000 tons of CO2 less for the fries from Lutosa

This is, of course, happening in Belgium: John Cockerill is helping French fries producer Lutosa to reduce its carbon footprint and to produce in an eco-responsible way. It is installing biogas co-generation at its Leuze-en-Hainaut site, which will enable it to reduce its CO2 emissions by 9 000 tons a year.

The installation consists of a 1.5 MW electric motor, a 20 bar steam boiler, an acoustic box and auxiliary equipment. John Cockerill is taking charge of the implementation from A to Z: the design, supply and delivery, construction and assembly, on-site installation and commissioning. The start-up is planned for the second half of 2022.

3 applications, 3 combinations of technologies

« With our integrated renewable solutions, we are proud to participate in the decarbonization of the economy and the fight against climate change. »

Dieter Hasevoets, Manager of Integrated Renewable Solutions activities

- Copied

Hydrogen: in pole position to decarbonize the economy

Five years after its strategic and pioneering decision to invest in the hydrogen sector, John Cockerill saw its technological and commercial leadership strengthened in 2021. In addition to the design and supply of electrolyzers, John Cockerill worked on the development of gigafactories in several countries around the world this year, with France and India in the lead. This dual position as the world leader in the market for large-capacity electrolyzers and a pioneer in gigafactories makes John Cockerill a major player in the decarbonization of industries and mobility.

The most powerful electrolyzers in the world

In 2021, John Cockerill designed, produced and delivered two electrolyzers of 1 300 Nm3/h and 6.5 Megawatts of unit capacity to China Huaneng Group. These electrolyzers, the most powerful in the world, are a technological innovation straight out of the workshops of Cockerill Jingli Hydrogen, the Group’s Chinese subsidiary. It should be noted that John Cockerill took 100% control of this subsidiary during the year, acquiring all the shares and full intellectual property of the technologies.

The teams celebrated this technological world record in the presence of the customer, local authorities, suppliers and research institutes. This industrial prowess is accompanied by an innovative force: our R&D teams have continued their research to further increase the capacity of John Cockerill electrolyzers, which are already the most impressive in the world, in terms of both their size and their power.

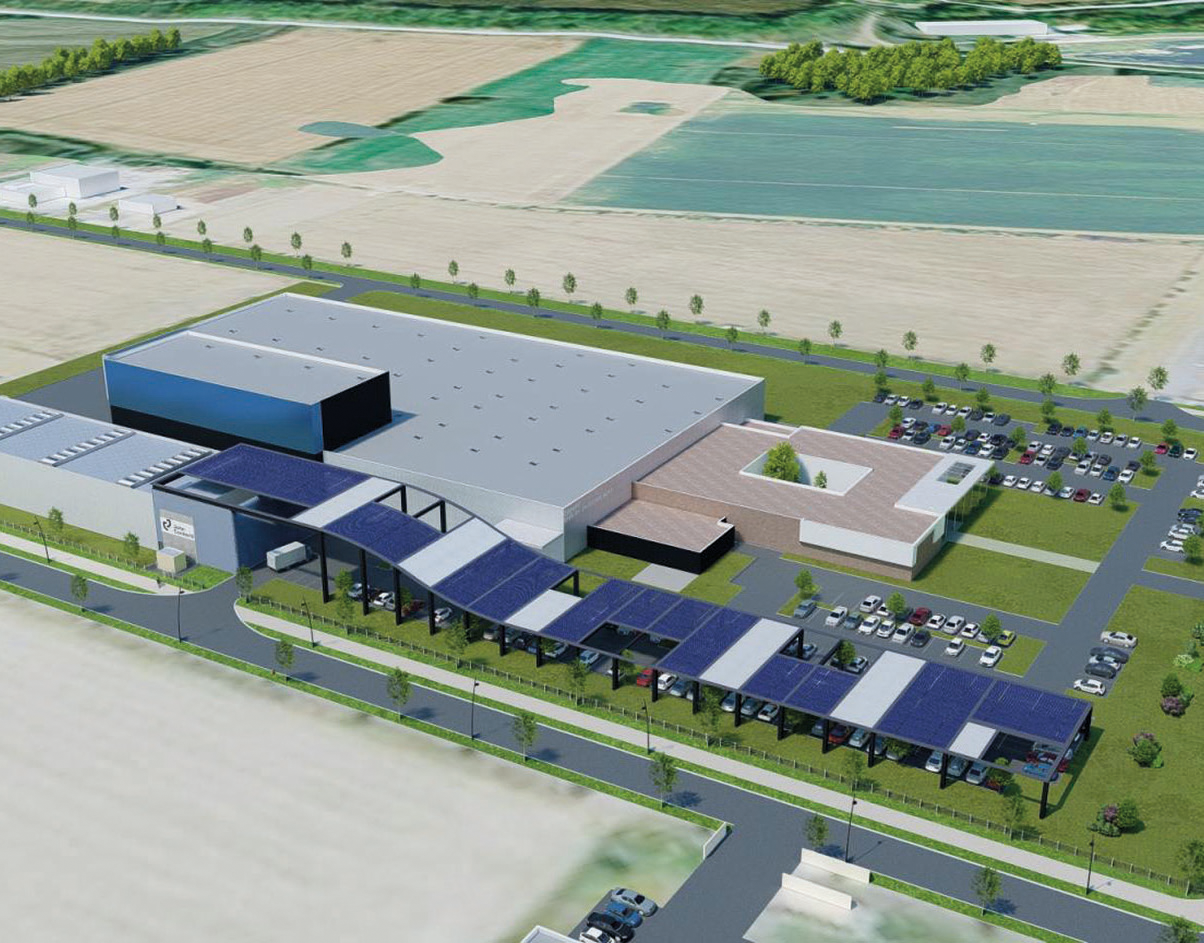

First gigafactory under construction

In 2021, John Cockerill completed several key stages in the establishment of a European industry for the manufacture of electrolyzers, starting with the filing of the permit applications necessary for the transformation of its Aspach-Michelbach site in Alsace (France) into a gigafactory. The new plant will be operational at the end of 2022, and the production of electrolyzers will gradually intensify: from 350 MW of capacity produced in 2023, it will reach one gigawatt before the end of the decade.

With the construction of gigafactories, John Cockerill is facilitating access to decarbonized energy, and supporting the deployment of hydrogen sectors in the four corners of the world. A partnership with Greenko, the Indian leader in renewable energies, for the deployment of gigafactories in India was concluded in 2021. Other contacts have been made elsewhere in the world. This is the case in Australia, Saudi Arabia and Morocco, where John Cockerill is cooperating with leading local players in setting up hydrogen sectors.

First European order

Hydrogen produced from renewable energy is of interest to European industrialists wishing to decarbonize their activities. Among these, the Spanish oil company Repsol ordered a 2.5 MW pressurized alkaline electrolyzer from John Cockerill this year in order to reduce its environmental footprint.

This first European reference for John Cockerill will generate the first renewable hydrogen in the Basque Country. In particular, it will supply buses and light vehicles at the logistics platform of the Petronor refinery, the first hydrogen station in the Basque Country.

Following China, where the hydrogen market is already well developed, Europe and the rest of the world should soon see the launch of hydrogen sectors, whether for the decarbonizing of mobility or of various industries, such as petrochemicals and steel-making first.

« With 33% of the market share of large capacity alkaline electrolyzers in 2021, we are consolidating our global leadership and demonstrating our ability to support global markets on the path to the decarbonization of industry and mobility. »

Raphaël Tilot, Head of Renewables and Hydrogen activities

Collaborations with a green future

John Cockerill stepped up its cooperation activities within the European hydrogen sector in 2021. It has thereby taken part in the work of the France Hydrogène association and of the Hyve consortium in Belgium, with Colruyt, DEME and Flemish research centers.

It has also taken part in two pioneering collaborative projects, which made significant progress in 2021: H2GridLab, which was initiated by the Brussels electricity and gas network operator Sibelga, aims to develop a ’Power-to-Gas‘ pilot based on green hydrogen via a Fluxys station. Columbus, which is being developed together with Carmeuse and Engie, is set to enable the capture and use of carbon from a new type of lime kiln.This CO2 is combined with green hydrogen, produced by a 75 MW electrolysis plant, to become e-methane, a renewable gas. Winner of a Febeliec Award this year, Columbus is the largest project of its type in the world.

In addition, John Cockerill has also joined forces with the Belgian consortium Hyoffwind and with BESIX to build a Power-to-Gas installation in Zeebrugge (Belgium). Objective: to convert renewable electricity from wind turbines in the North Sea into green hydrogen.

151

This is the number of megawatts installed worldwide with electrolyzers from John Cockerill, compared to a global installed market of 458 MW.

1300Nm3/h and 6,5 MW

This is the record unit capacity offered by the alkaline electrolyzers from John Cockerill.

- Copied

Wind power is breezing ahead

The wind turbine maintenance adventure began for John Cockerill in 2008. In 2021, its teams almost doubled the number of wind turbines under maintenance contract, going from 110 wind turbines in 2020 to 200 in 2021. In Belgium, France and Brazil, the energy transition specialists at John Cockerill aim to improve the reliability, performance and efficiency of wind farms in strict compliance with safety rules.

Since starting work in the wind power sector, John Cockerill has never stopped diversifying its offering. It now offers a full range of services: in addition to maintenance services, the supply of spare parts, inspections, blade repairs and end-of-warranty equipment audits, John Cockerill also offers the replacement and repair of major components.

On land and at sea

John Cockerill won several offshore and onshore operations and maintenance (O&M) contracts in 2021.

The company won orders for onshore wind power in France and Brazil, and concluded major blade maintenance and repair contracts. In Brazil, its specialists will maintain wind farms for an additional 3 years, while, in France, they will provide maintenance, including the supply of spare parts, to two new wind farms.

In Belgium, John Cockerill won the renewal of a contract for the maintenance of an offshore wind farm located off Ostend, for a period of 4 years. Some 21 of its specialists have been maintaining it since 2008, to the great satisfaction of their client.

800.000

This is the number of tons of CO2 that John Cockerill’s work on wind turbines helps to avoid each year.

500.000

This is the number of homes supplied with renewable energy from wind turbines maintained by John Cockerill technicians.

200

This is number of wind turbines maintained by John Cockerill’s teams in 2021.

130

This is the number of wind experts deployed by John Cockerill in France, Belgium and Brazil.

John Cockerill’s leitmotif in wind power: extending the life of wind turbines to develop access to renewable energy.

Top flight technicians

SupAirVision, first fundraising

Industrya, the investment fund set up in 2020 by John Cockerill and 4 Belgian public partners, began its support of French startup SupAirvision in 2021. In view of John Cockerill’s experience in wind power, the industrial link with SupAirVision was self-evident. SupAirVision now has the support necessary to digitalize the diagnosis of wind turbine blades in Europe and around the world. Its innovation efforts will be mobilized, in particular, to enable the development of Volta, the first system for diagnosing lightning paths by drone, and its deployment on the German and Northern European markets.

In addition to the quality of the services offered, SupAirVision was also an obvious choice due to its ability to meet the needs of our time: to develop products that are needed today and to offer innovative technical and operational solutions.Through its onshore and offshore wind turbine maintenance activities in France, Belgium, Spain, Brazil and Morocco, John Cockerill will undoubtedly have a role to play in supporting the development of SupAirVision.

- Copied

50 years in the service of low-carbon energy: nuclear power

With the strength of more than half a century of experience in keeping nuclear power plants safe behind it, John Cockerill contributes to maintaining the safety of the sites and components of the power plants, as well as the safety of the populations, local residents and professionals who live around them. This is because participating in the transition to low-carbon energies not only means developing renewable solutions, but also taking care of the nuclear sector.

13

Recognized performance in France

After having passed the milestone of a million hours of ‘tap & pipework’ worksites in 2019, John Cockerill moved up to a new level in 2021 when it became the second largest national player in this segment, seeing itself mandated with the maintenance of 12 nuclear units: four at Tricastin, four at Cattenom, two at Chooz and two at Belleville.

The diversification of activities and clients in ‘Large Component Operations’ was also concretized by a contract with Framatome for maintaining equipment before the start of the EPR at Flamanville.

These contracts bear witness to the confidence of the nuclear operator and of major clients in the sector, convinced by the daily commitment of the teams of John Cockerill in order to guarantee safer and better performing equipment.

Belgium: John Cockerill remains a partner for both maintenance and dismantling

The debate on the extension of the operation of nuclear power plants has raged for a long time in Belgium and continued to do so in 2021. John Cockerill leaves this political, or even ideological debate to the competent authorities, and is at their disposal as a technological expert. For whatever the outcome, one thing is certain: John Cockerill will remain a partner of choice when it comes to supporting the operators of the country’s nuclear power plants.

In 2021, John Cockerill thereby accepted the invitation from Belgian Ministers to organize the end of life of nuclear reactors, and to manage the dismantling activities. In the event of the creation of a Belgian dismantling sector, John Cockerill intends to play a central role: already the partners of existing plants, John Cockerill’s teams have the skills to dismantle them if a decision is taken to do so.

Training, a guarantee of performance and safety

Solar at the service of SMRs

- Copied

Producing responsibly

Producing responsibly